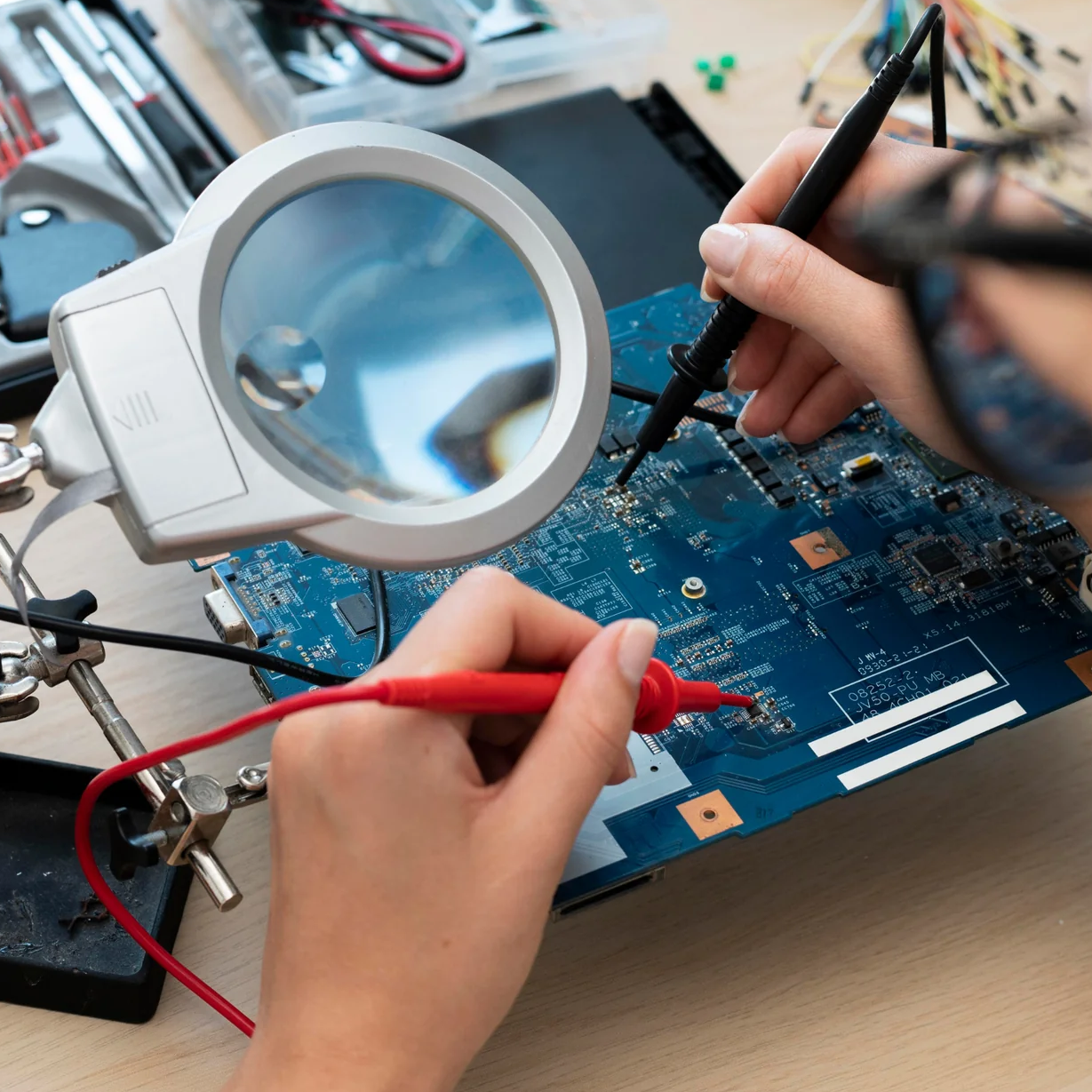

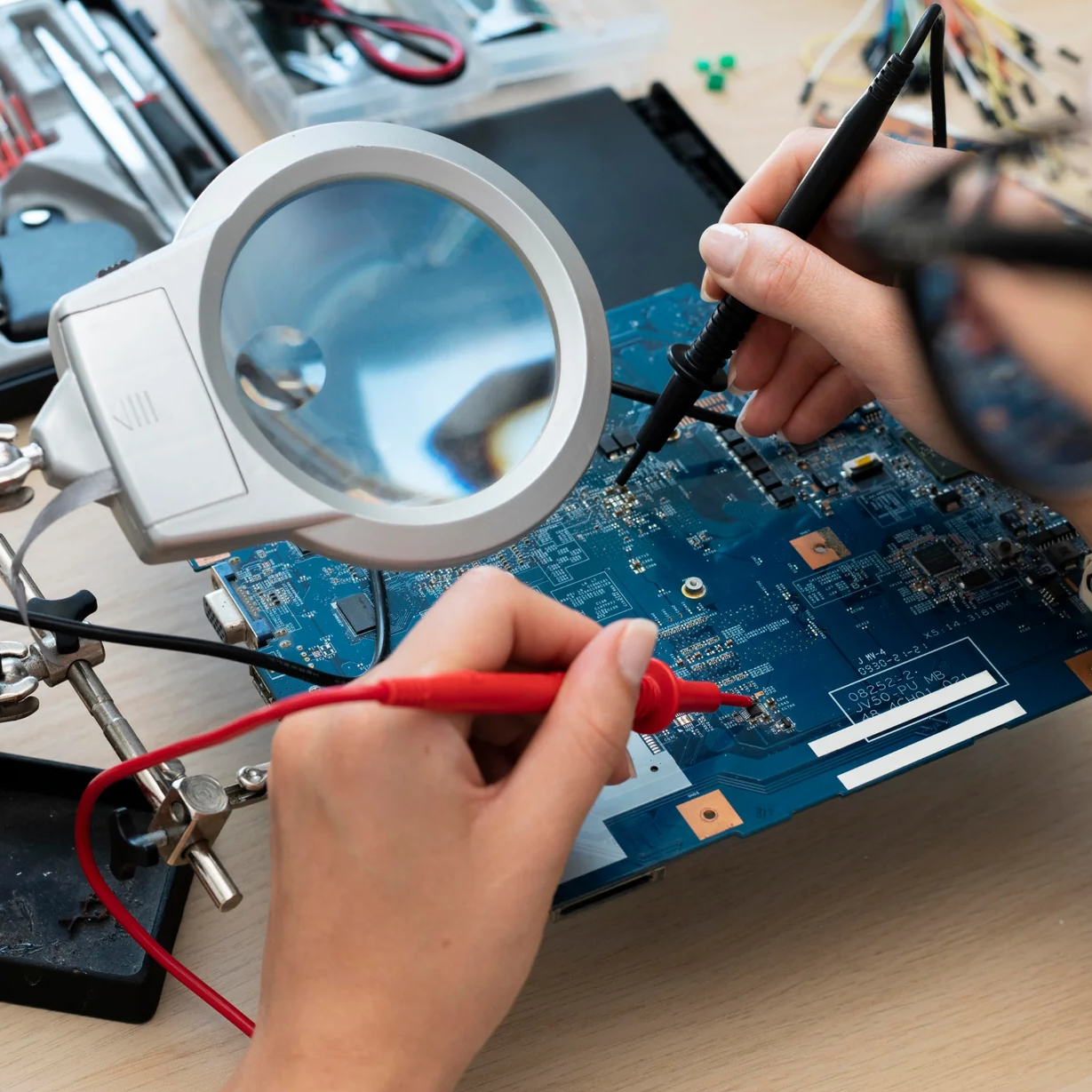

As part of our comprehensive preventative maintenance service, we carefully disassemble the device to assess its internal components. The maintenance process includes the following steps:

-

Device Inspection: We conduct a thorough visual inspection of the device, focusing on potential wear and tear or any signs of damage.

-

Cleaning of Internal Components: We carefully clean the circuit board, remove dust, debris, and any contaminants that could interfere with the device's performance. This also includes cleaning solder joints and other critical connections to ensure optimal conductivity.

-

Solder Joint Examination and Maintenance: We inspect all solder joints for any signs of cracking, oxidation, or wear. Necessary repairs or touch-ups will be made to maintain the integrity of these connections.

-

Connector and Cable Check: We test all connectors and cables for secure attachment and proper functionality, ensuring they are free of corrosion or other issues that could affect performance.

Functional Testing: After reassembly, we perform a series of functional tests to confirm that the device is operating within manufacturer specifications and delivering accurate results.

This detailed maintenance helps extend the lifespan of the device and ensures it continues to provide reliable and accurate measurements.